- July 11, 2023

- Posted by: clakaf

- Category: Uncategorized

QForm 3D 12: The Ultimate Software for Metal Forming Simulation and Optimization

If you are looking for a professional engineering software that can help you simulate, analyze and optimize metal forming processes such as forging, extrusion, rolling and more, then you should consider QForm 3D 12. QForm 3D 12 is the latest version of the QForm software that has been developed by QForm Group, a leading provider of metal forming simulation software for over 25 years.

QForm 3D 12 has many features and benefits that make it stand out from other metal forming simulation software in the market. Here are some of them:

- QForm 3D 12 has the most user-friendly interface in the market, which allows you to easily prepare the initial data, run the simulation and view the results in one window. You can also modify the simulation parameters and the finite element mesh on the fly, without interrupting the simulation process.

- QForm 3D 12 has the fastest simulation time thanks to the most modern programming techniques and the effective use of multicore processors and computer resources. You can also view the results in real time even while a complicated simulation is running, thanks to the separate but concurrent solver and user interface.

- QForm 3D 12 has a powerful and universal software core that can simulate any kind of metal forming processes, including cold, warm and hot die forging, open die forging, rolling, profile extrusion, hydroforming, cross-wedge rolling, cross-roll piercing and more. You can also simulate complex tools, multiple workpieces of different materials, spring loaded tools and load holders, visco-plastic and elastic-plastic deformation, thermo-elastic-plastic problems and more.

- QForm 3D 12 has a fully automatic and highly adaptive mesh generator that can handle large deformations, contact problems, material flow and other challenges in metal forming simulation. The mesh generator ensures high accuracy and reliability of the simulation results without requiring manual intervention or mesh refinement.

- QForm 3D 12 has a variety of special modules that can enhance your metal forming simulation capabilities, such as microstructure prediction, heat treatment simulation, user subroutines assignment and more. You can also integrate QForm 3D 12 with other software such as CAD/CAM systems, optimization tools, experimental data analysis and more.

With QForm 3D 12, you can achieve your metal forming goals faster and easier than ever before. You can design and optimize your metal forming processes, reduce material waste and energy consumption, improve product quality and performance, solve complex metal forming problems and more.

How to Use QForm 3D 12 for Metal Forming Simulation and Optimization

If you are interested in using QForm 3D 12 for your metal forming simulation and optimization needs, here are some steps that you can follow:

- Download and install QForm 3D 12 from the official website of QForm Group. You can also request a free trial version or a demo version to test the software before purchasing it.

- Launch QForm 3D 12 and create a new project. You can choose from various templates or start from scratch. You can also import your existing data from other software or formats.

- Define the initial data for your simulation, such as the geometry of the workpiece and the tool, the material properties, the boundary conditions, the process parameters and more. You can use the built-in tools and wizards to help you with this step.

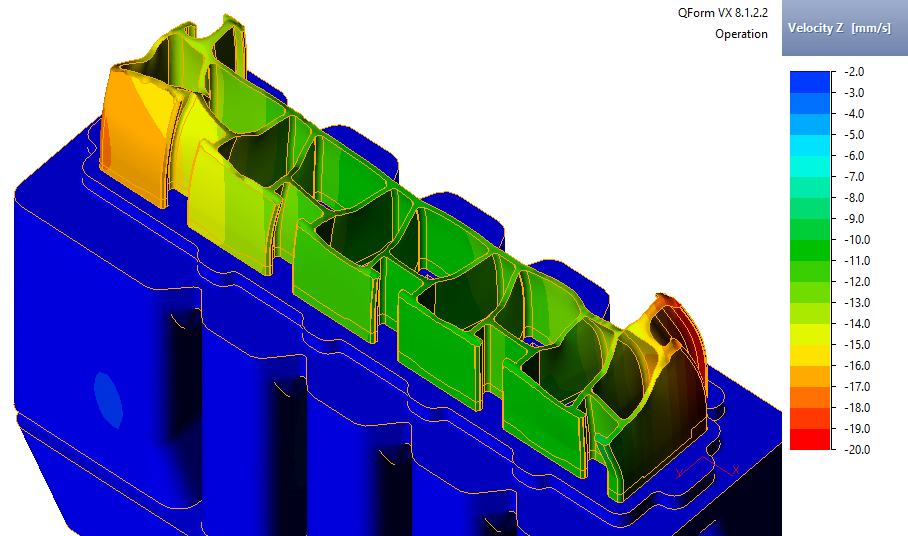

- Run the simulation and monitor the progress and results in real time. You can pause, resume, stop or modify the simulation at any time. You can also view various output data such as stress, strain, temperature, force, velocity, displacement and more.

- Analyze and optimize your simulation results using the powerful post-processing tools in QForm 3D 12. You can compare different scenarios, perform sensitivity analysis, evaluate quality indicators, predict microstructure and heat treatment effects and more.

- Export your simulation results to other software or formats for further processing or presentation. You can also generate reports and documentation for your simulation project.

QForm 3D 12 is a versatile and user-friendly software that can help you with any metal forming simulation and optimization task. Whether you are a beginner or an expert, you can benefit from the features and benefits of QForm 3D 12.

What are the Advantages of QForm 3D 12 over Other Metal Forming Simulation Software?

QForm 3D 12 is not the only metal forming simulation software in the market, but it is certainly one of the best. Here are some of the advantages that QForm 3D 12 has over other metal forming simulation software:

- QForm 3D 12 has a more realistic and accurate simulation model that can capture the complex physics and mechanics of metal forming processes. QForm 3D 12 uses a fully coupled thermo-mechanical approach that considers the interaction between the workpiece and the tool, as well as the heat transfer and friction effects. QForm 3D 12 also uses an adaptive remeshing technique that can handle large deformations, contact problems and material flow without compromising the quality of the mesh or the results.

- QForm 3D 12 has a more comprehensive and flexible simulation scope that can cover any kind of metal forming processes and scenarios. QForm 3D 12 can simulate cold, warm and hot die forging, open die forging, rolling, profile extrusion, hydroforming, cross-wedge rolling, cross-roll piercing and more. QForm 3D 12 can also simulate complex tools, multiple workpieces of different materials, spring loaded tools and load holders, visco-plastic and elastic-plastic deformation, thermo-elastic-plastic problems and more. QForm 3D 12 can also integrate with other software such as CAD/CAM systems, optimization tools, experimental data analysis and more.

- QForm 3D 12 has a more user-friendly and efficient interface that can help you save time and effort in your simulation project. QForm 3D 12 has a single window interface that allows you to prepare the initial data, run the simulation and view the results in one place. You can also modify the simulation parameters and the finite element mesh on the fly, without interrupting the simulation process. You can also view the results in real time even while a complicated simulation is running, thanks to the separate but concurrent solver and user interface.

- QForm 3D 12 has a more affordable and flexible pricing model that can suit your budget and needs. QForm 3D 12 offers various licensing options such as perpetual licenses, annual licenses, monthly licenses and cloud licenses. You can also choose from different editions such as basic edition, standard edition and professional edition. You can also customize your QForm 3D 12 package by adding or removing special modules such as microstructure prediction, heat treatment simulation, user subroutines assignment and more.

QForm 3D 12 is a superior metal forming simulation software that can help you achieve your metal forming goals faster and easier than ever before. You can design and optimize your metal forming processes, reduce material waste and energy consumption, improve product quality and performance, solve complex metal forming problems and more.

How to Learn QForm 3D 12 and Improve Your Metal Forming Simulation Skills?

If you want to learn QForm 3D 12 and improve your metal forming simulation skills, there are many resources and opportunities that you can use. Here are some of them:

- QForm 3D 12 has a comprehensive and easy-to-follow user manual that covers all the aspects and features of the software. You can access the user manual from the help menu or download it from the official website of QForm Group. The user manual also contains many examples and tutorials that can help you get started with QForm 3D 12.

- QForm 3D 12 has a dedicated and responsive technical support team that can help you with any questions or issues that you may have with the software. You can contact the technical support team by email, phone or online chat. You can also submit your feedback or suggestions for improving QForm 3D 12 through the online form.

- QForm 3D 12 has a vibrant and active user community that can help you learn from other users and experts. You can join the QForm Forum, where you can ask questions, share your experience, exchange ideas and tips, and participate in discussions with other QForm users. You can also follow the QForm Group on social media platforms such as Facebook, Twitter, LinkedIn and YouTube, where you can get the latest news, updates, events and videos about QForm 3D 12.

- QForm 3D 12 has a regular and diverse schedule of events and activities that can help you learn more about the software and metal forming simulation. You can attend the QForm Seminars, where you can learn about the new features and improvements of QForm 3D 12, as well as the best practices and case studies of metal forming simulation. You can also attend the QForm Online School, where you can get a comprehensive and interactive training on QForm 3D 12 from the experts. You can also attend the QForm UK Forum, where you can network with other QForm users and experts, as well as present your own work and achievements with QForm 3D 12.

QForm 3D 12 is a powerful and user-friendly software that can help you with any metal forming simulation and optimization task. Whether you are a beginner or an expert, you can benefit from the resources and opportunities that QForm Group offers to help you learn QForm 3D 12 and improve your metal forming simulation skills.

https://github.com/1detonFspira/background-removal-js/blob/main/examples/Download%20Deewaar%20Full%20Movie%20720p%20-%20The%20Film%20That%20Made%20Amitabh%20Bachchan%20the%20Angry%20Young%20Man%20of%20Bollywood.md

https://github.com/3centtissyngnu/mdBook/blob/master/guide/Screen%20recorder%20cracked%20How%20to%20download%20and%20install%20the%20best%20software%20for%20free.md

https://github.com/8destrucmiswo/awesome-free-chatgpt/blob/main/.github/ISSUE_TEMPLATE/Statistics%20And%20Data%20Analysis%20For%20Nursing%20Research%20(2nd%20Edition).epub%20The%20Essential%20Resource%20for%20Evidence-Based%20Nursing.md

https://github.com/1lustdiatisbu/prettydiff/blob/master/css/Comfort%20Food%20by%20Kitty%20Thomas%20Download%20the%20Epub%20and%20Prepare%20to%20be%20Shocked.md

https://github.com/8listurFpaeke/pyswarms/blob/master/docs/Luther%20Vandross%20Greatest%20Hits%201981-1995%20Full%20Album%20Zip%20Stream%20or%20Download%20the%20Classic%20Hits%20of%20the%20RB%20Icon.md

https://github.com/amilWlecge/django-jet/blob/dev/docs/Where%20to%20Find%20Sony%20Vaio%20Windows%207%20Recovery%20Disk%20Torrent-adds%20Full%20and%20How%20to%20Use%20It.md

https://github.com/8glycolgratke/server/blob/master/UlteriusAgent/Properties/Sediv%202.3.5.0%20hard%20drive%20repair%20tool%20575%20How%20to%20get%20the%20best%20results%20with%20it.md

https://github.com/9inprovZexru/awesome-free-chatgpt/blob/main/.github/Cios%20Waninkoko%20Yeyovalium%20Net%2012%20The%20Ultimate%20Guide%20for%20Wii%20Hackers.md

https://github.com/inpalqueka/questdb/blob/master/artifacts/tsbs/Tlchargez%20Kim%20Ki%20Duk%203%20Iron%20Torrent%20et%20dcouvrez%20loriginalit%20du%20cinma%20coren.md

https://github.com/8diamuluwo/JetBrainsMono/blob/master/.github/BOSCH%20ESI%20tronic%202012%201%20DVD1%20DVD2%20DVD3%20The%20Benefits%20and%20Features%20of%20the%20Leading%20Diagnostic%20System%20for%20Cars%20and%20Trucks.md

86646a7979